Wishful Freeform RX Lens

Production Process

The production process of Freeform RX Lenses involves the following key steps:

1. Prescription Analysis and Lens Blank Selection: The optometric prescription resulting from the eye exam is checked and calculated, and then the necessary production data is generated in the form of a process sheet. Two semi-finished lens blanks (for left eye and right eye) are selected based on the prescription requirements.

2. Blocking: A protective layer is applied to the front surface of the semi-finished lens and fixed to a metal or alloy block. The lenses may be secured to the block during subsequent grinding and polishing processes.

3. Generating (Grinding): The front surface already has corrected vision, and this step is simply to generate the design and prescription parameters to the back surface of the blanks. Precision grinding is carried out by means of a computer-controlled machine (CNC). In the case of free-form lenses, this process creates the desired complex curves based on individual prescriptions.

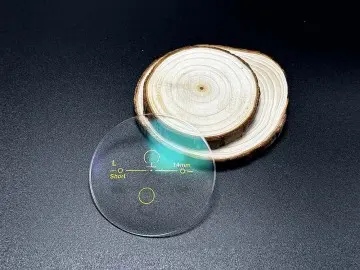

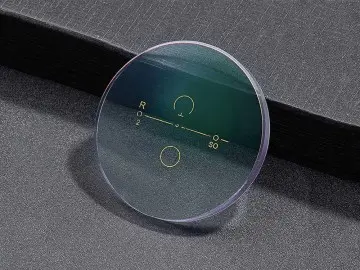

4. Polishing & Laser Engraving: After grinding, the surface of the lenses will be polished for optical clarity and smoothness, which is essential for coating. Some manufacturers may complete the laser engraving of micro-labels on the lenses.

5. De-blocking and Cleaning: After polishing, the lenses will be removed from the blocker, and then be cleaned in pure water with specialized cleaning agents and then conveyed to the next station.

6. Tinting: The lenses will be tinted if requested. Put the plastic lenses in a dye bath or coat the glass lenses with a metal oxide layer.

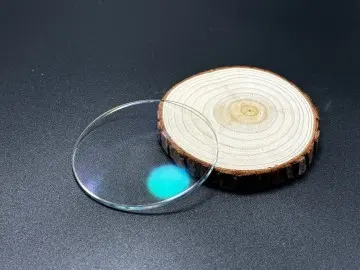

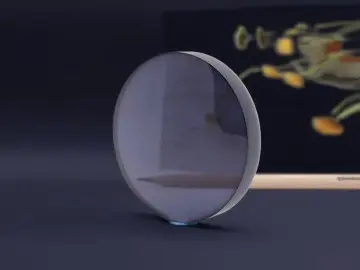

7. Coating: Coating makes lenses scratch-resistant, durable, and reduces irritating reflections. First, the lenses are hardened with a hard solution. Next, an anti-reflective layer is added to the lenses in a vacuum deposition process. Then, the final layer of coating gives the lenses a smooth surface that is smudge and water-resistant and reduces reflections.

8. Inspection and Quality Control: Each lens is thoroughly inspected before delivery. Quality inspection includes visual inspection for dust, scratches, damage, and coating color consistency. Instruments are used to check the diopter, axis, thickness, design and diameter to ensure the lenses meet the required specifications and quality standards.

Our Strengths

Wishful Optical is a professional freeform RX lenses manufacturer. Our freeform RX eyeglass lenses are crafted using state-of-the-art technology, ensuring precise customization and exceptional clarity.

Index Available: Available in every index 1.49, 1.56, 1.59, 1.60, 1.67, 1.74.

Digital Surfacing Technology: Use the most advanced cutting-edge digital technology to deliver a sharper vision and a more personalized fit.

CAD Assistance and CNC Machining: Using computer-aided design and computer-controlled machinery to precisely surface the lenses based on the individual's prescription and frame shapes.

Designs Available: Opto Tech and IOT designs for different optical and functional requirements.

Enhanced Visual Range: Customized freeform lenses provide a wider field of vision, giving the wearer a clearer view.