Polycarbonate Anti Blue Light Lens

Product Specification

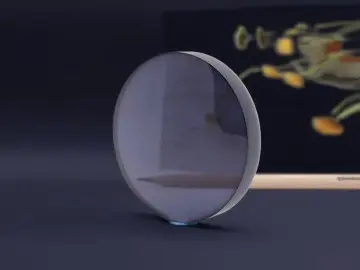

Material |

Polycarbonate |

Index |

1.591 |

Abbe Value |

32 |

Specific Gravity |

1.20 |

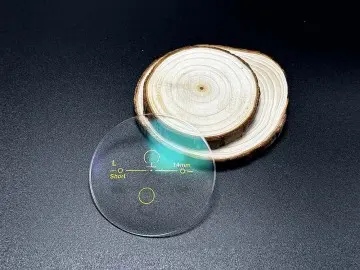

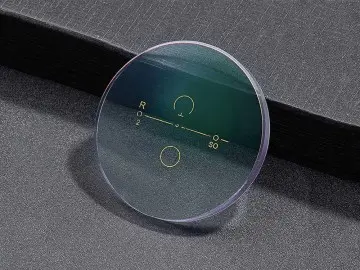

Diameter |

75mm 70mm |

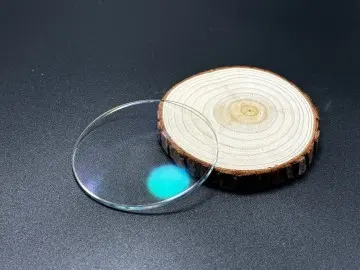

Transmission |

99% |

UV Protection |

UV380/UV420 |

Coating Choice |

Green coating & Blue coating |

Product Description

As a high-performance thermoplastic polymer, polycarbonate was initially developed by scientists to enable space exploration equipment to withstand the unique conditions of space, which is why it is often referred to as "space lenses." It is one of the five major engineering plastics known for its excellent transparency and has been one of the fastest-growing general engineering plastics in recent years. Currently, it is widely used in fields such as optics, electronics, construction, automotive, and healthcare, and is particularly suitable for making eyeglass lenses. Impact resistant polycarbonate lenses offer 100% inherent UV protection and are often used in safety glasses, sports eyewear and children’s glasses.

Product Advantages

Polycarbonate material has the advantages such as ultra-lightness, strong impact resistance, UV protection, and excellent light transmission. They are widely used as transparent materials in engineering plastics due to their good stability and non-conductive properties, which allow for a broad range of applications. Lenses made from polycarbonate naturally possess these advantages, making them particularly suitable for individuals with high prescriptions, those who value aesthetics, athletes, children, and the elderly. For instance, most eye care professionals will strongly advise parents to choose polycarbonate lenses for their children's glasses.

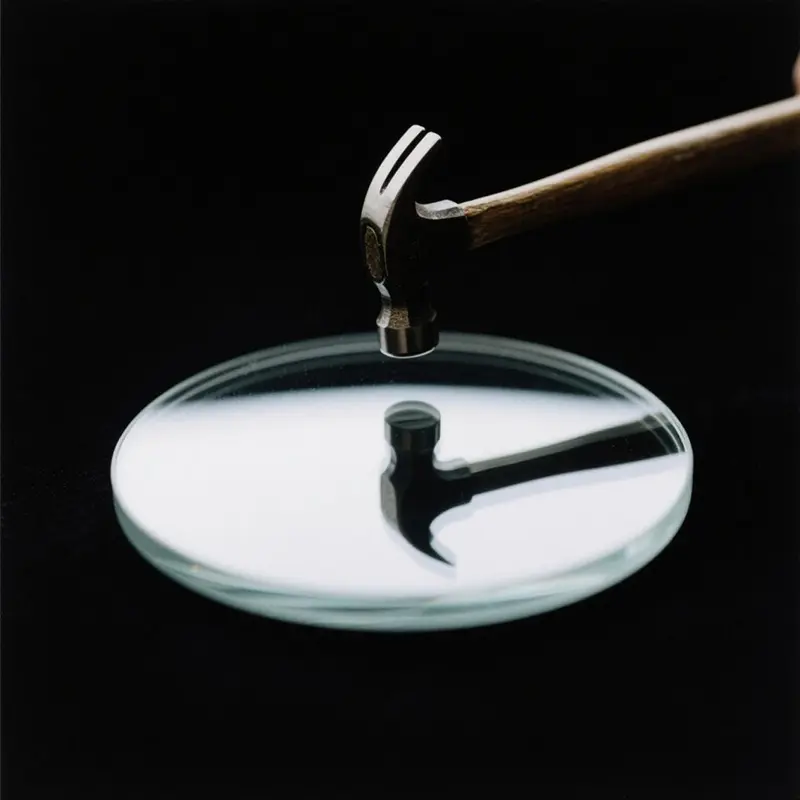

General resin lenses are thermosetting materials, meaning the raw material is in a liquid state and forms solid lenses upon heating. In contrast, PC lenses are thermoplastic materials, where the raw material is solid and is molded into lenses upon heating. As a result, these lenses can deform when excessively heated and are not suitable for high humidity and heat environments. Polycarbonate impact resistant lenses are extremely tough and shatterproof (2cm can be used for bulletproof glass), hence they are also known as safety lenses. With a specific gravity of only 2 grams per cubic centimeter, they are currently the lightest material used for lenses.

Care and Maintenance

Although polycarbonate eyeglass lenses have good wear resistance, users should still pay attention to the following points in daily use to maintain the lifespan and clarity of the lenses:

1. Avoid contact with sharp objects: Try to prevent PC lenses from coming into contact with sharp or abrasive items to avoid scratches.

2. Use specialized tools for cleaning: Always use a specialized glasses cleaning cloth or a soft cloth to wipe the lenses, and avoid using abrasive cleaners or tissues to prevent scratching.

3. Take protective measures when storing: When not using polycarbonate eyeglasses, it is best to store them in a specialized glasses case to avoid friction with other items.

4. Avoid high-temperature environments: PC lenses are sensitive to high temperatures, so do not expose them to such environments for extended periods to prevent damage.