The Upgrade of Danyang Glasses Industry

Known for "the city of glasses", Danyang is the world's largest production hub for eyeglass lenses. More than 400 million lenses are produced annually in the city, accounting for 70% of China's total output and 50% of the world's. These products are exported to more than 150 countries and regions.

On July 14th, CCTV's Finance Channel program "Economic Half Hour" broadcast "An Upgrading Model of Made in China: Danyang Glasses," offering a detailed report on the Danyang glasses industry's determined efforts to transform and upgrade.

From 2 workshops to 2,000 enterprises, it has taken this small city 40 years to build the world's most complete lens industry chain. However, for quite a long time, Danyang eyeglasses have been famous for their massive output and competitive prices, which is also accompanied by fierce price fights and “involution” competition. Competing on price and quantity was once the survival rule for many manufacturers. The gross profit margin for a pair of domestically produced resin lenses is a mere 10%, less than a tenth of that of international brands. But now, the glasses industry in Danyang does not rely on low prices, but also strives to tear off the “cheap” label and breakthrough into high-precision, high-standard, and high-value-added.

In recent years, many lens manufacturers in Danyang have transformed their focus from bulk sales to refined, differentiated, and customized lens markets. Currently, a notable number of Danyang lens companies are leveraging innovation to escape the "low-price" trap.

In the global lens market, progressive lenses in developed countries hold a considerable share of about 50% of the population. However, in China, the progressive lenses market share lingers in the single digits. The key is that imported equipment is expensive and cannot be replaced by domestic alternatives.

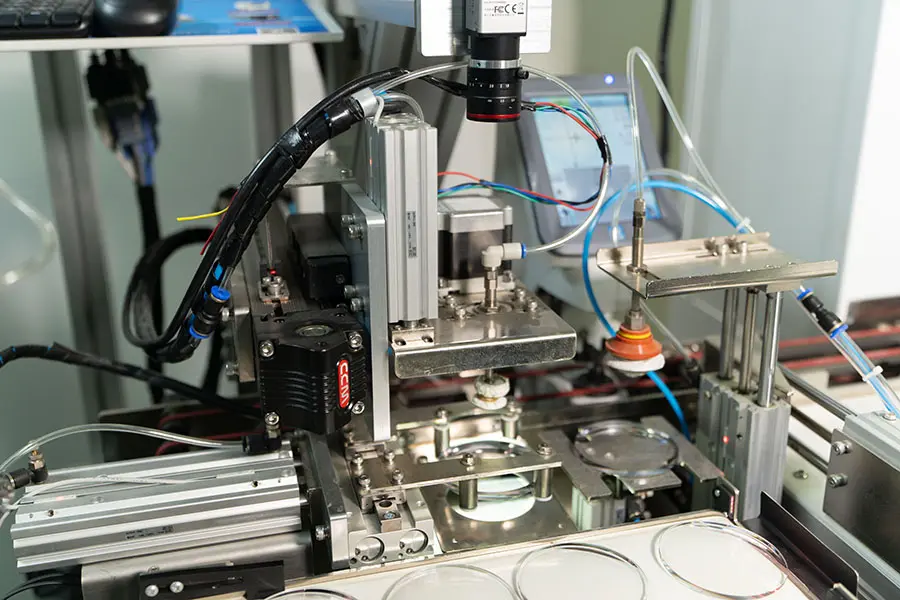

The turning point came from a group of young engineers who successfully reduced the processing time from 300 seconds to 60 seconds per lens and developed a replacement product with a price that is only half the cost of foreign equipment, marking Danyang lenses' transition from the "millimeter era" to the "nanometer stage." Up to now, Danyang glasses industry has a total of 22 provincial-level specialized and innovative enterprises, 7 advanced intelligent factories, 4 industrial design centers, and over 370 invention patents.

Statistics show that the export value of Danyang glasses reached 1.716 billion yuan in the first four months of 2025, a year-on-year increase of 4.3%, with products being exported to more than 150 countries and regions. At the same time, cross-border e-commerce has grown explosively. Some companies experience a 54.24% increase in export value through TikTok live streaming. High value-added lenses, such as multi-point defocus and progressive multifocal lenses, are rapidly penetrating into overseas markets.

Initially, the production technology of multi-point defocusing lenses is in the hands of foreign brands, and a pair of lenses could be sold for 4,000 to 5,000 yuan. Today, China's myopia control lenses not only match foreign products in effectiveness and quality but are also priced at only one-third of their competitors. So that our products occupy more overseas markets.

In 2024, the Jiangsu Provincial Department of Science and Technology strongly supported the development of the Danyang lens industry: providing cumulative support for over 20 science and technology projects in eyewear companies, allocating more than 18 million yuan in financial funding, establishing 6 provincial-level engineering technology research centers, and fostering 45 high-tech enterprises as well as nearly 100 science and technology-based SMEs to provide innovative support for "Danyang Made" products. A large number of innovative, high-value-added products are emerging, including VR and AR glasses, and customized sports glasses.

Currently, over 80,000 people in Danyang are engaged in the optical industry. Each year, more than 1.2 million people from all over the world visit Danyang for "eyewear tourism." The Danyang government has positioned the Glasses Town as a "new eyewear destination in the Yangtze River Delta" and has promoted the transformation of Danyang from a “production base” to a “global optical R&D center”.

The transformation of Danyang lenses exemplifies "Made in China" evolving into "Intelligent Manufacturing in China," demonstrating that the real industrial upgrading requires seizing technological leadership and gaining a voice in setting standards.