Brief Analysis of the Film Layer of Eyeglass Lenses

Lenses are no strangers to many people, serving as the primary component in myopia correction eyewear. Lenses feature various coatings such as green coatings, blue coatings, blue-violet coatings, and even luxury gold coatings. Coating wear and deterioration stand as one of the main reasons for eyewear replacement. In this issue of Window of Optometry, we will explore the essential knowledge about lens coatings.

The Development of Lens Coating

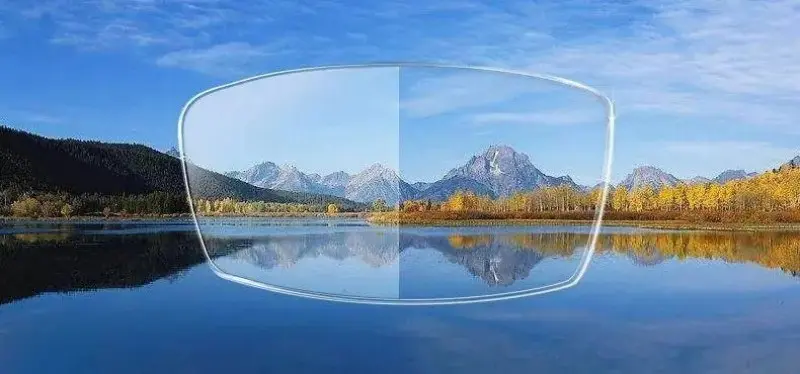

Before the advent of resin lenses, glass lenses were predominantly used in the market. Glass lenses offer advantages such as a high refractive index, excellent light transmittance, and superior hardness. However, they also have notable drawbacks: susceptibility to shattering, significant weight, and safety concerns.

To address these limitations of glass lenses, manufacturers have researched and developed various alternative materials. Yet, most solutions have proven suboptimal, as each material exhibits a mix of strengths and weaknesses without achieving balanced performance—this includes contemporary resin lenses (resin materials). For modern resin lenses, coating is an essential manufacturing process. Resin materials themselves are categorized into multiple types, such as MR-7, MR-8, CR-39, PC, and NK-55-C, among others. These diverse resin materials demonstrate varying characteristics. Additional resin variants also exist with distinct material properties. Both glass and resin lenses inevitably produce specific optical phenomena when light interacts with their surfaces: reflection, refraction, absorption, scattering, and transmission.

The anti-reflective coating (AR coating) of lens coatings

Before reaching the lens surface interface, the light is 100% light energy. When it comes out of the lens back interface and enters the eyeball, it is no longer 100% light energy. The higher the percentage of light energy, the better the light transmittance, and the higher the image quality and resolution.

For a fixed lens material, reducing reflection loss is a common method to increase light transmittance. The more reflected light, the lower the light transmittance of the lens, and the worse the image quality. Therefore, anti-reflection has become a problem that must be solved for resin lenses, and anti-reflection film (anti-reflection film) has been applied to lenses (anti-reflection film was first used on some optical lenses).

Anti-reflection film uses the principle of interference to deduce the relationship between the light intensity reflectivity of the anti-reflection film layer of the coated lens and the wavelength of the incident light, the thickness of the film layer, the refractive index of the film layer, and the refractive index of the lens substrate, so that the light passing through the film layer offsets each other, reducing the loss of light energy on the lens surface, and improving the image quality and resolution.

Anti-reflection film mostly uses high-purity metal oxides such as titanium oxide and cobalt oxide, which are coated on the surface of the lens through evaporation (evaporation) to achieve a good anti-reflection effect. Anti-reflection film coating will often leave residue, and most of the film layers are green.

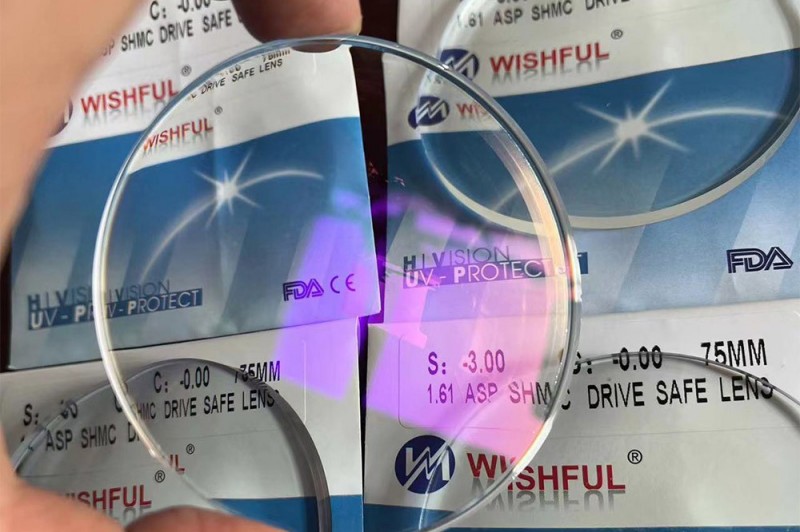

In principle, the color of the anti-reflection film can be controlled, for example, it can be produced into blue film, blue-purple film, purple film, gray film, etc. The process of producing different colored films is different. For example, the blue film means that the reflectivity must be controlled at a lower level, and the coating difficulty is greater than that of the green film, but the difference in light transmittance between the blue film and the green film may be less than 1%.

Blue films are generally found in mid-range and high-end lenses. In principle, blue films have higher light transmittance than green films (note that this is in principle), because light is a mixture of different wavelengths, and different wavelengths have different imaging positions on the retina. Normally, yellow-green light is imaged on the retina, and green light contributes more visual information, so the human eye is sensitive to green light.

Hard coating for lens coating

In addition to lens light transmittance, resin and glass materials have another significant drawback: insufficient lens hardness. The solution is to apply a hardening coating. Glass lenses have high surface hardness (they are not easily scratched by ordinary objects), but resin lenses are not the same—they can easily be marked when scratched by hard objects, indicating that resin lenses are not wear-resistant.

To improve the lens's abrasion resistance, a hardening coating must be applied to the lens surface. Hardening coatings often use silicon atoms for the hardening process, meaning a hardening solution containing an organic matrix and inorganic ultrafine particles, including silicon, is applied. This hardening coating provides both toughness and hardness (the lens surface layer is highly durable, while the lens substrate remains less brittle, unlike glass, which is prone to breaking).

The most common modern hardening coating technique is the dip-coating method. The hardening coating is relatively thick, approximately 3–5 μm. For resin lenses with a hardening coating, they can be identified by the sound they make when tapped on a table and the brightness of their color. Lenses that produce a crisp sound and have bright edges are those that have undergone hardening treatment.

Anti-Soiling Coating for Lens Coatings

Anti-reflective (AR) coating and hard coating are currently the two most fundamental layers for resin lenses. Typically, the hard coating is applied first, followed by the anti-reflective coating. Due to the limitations of current AR coating materials, there is an inherent contradiction between anti-reflective properties and stain resistance. Because the AR coating exists in a microporous state, it is particularly prone to staining on the lens surface.

The solution is to add an additional anti-soiling coating over the AR layer. This anti-soiling coating is primarily composed of fluorides, which seals the porous AR layer, reducing the contact area between water, oil, and the lens while preserving the optical performance of the AR coating.

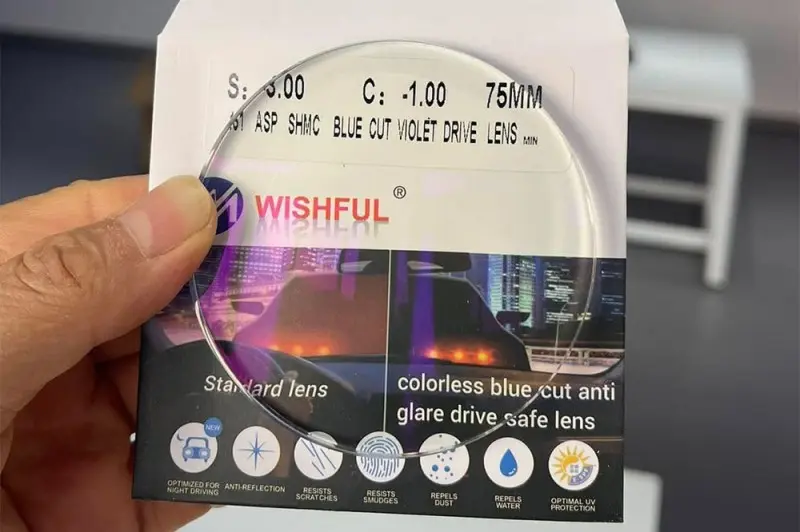

As demands diversify, more functional coatings have been developed, such as polarized coatings, anti-static coatings, blue light-blocking coatings, and anti-fog coatings. Even with the same lens material and refractive index, price differences exist between brands—or even within the same brand and material but across different product lines. One of the reasons for this variation lies in the lens coatings, as differences in coating technology and quality can significantly impact performance.

Modern eyewear products have achieved significant advancements in light transmission, scratch resistance, and anti-smudge performance through continuous upgrades in coating technology. The majority of resin lenses, PC lenses, and acrylic lenses now feature coating designs that meet everyday needs.

Eyeglasses are actually quite delicate products, largely due to the coating technology, which is particularly sensitive to temperature. If you notice any damage to the lens coating, it’s crucial to replace the lenses immediately—never continue using them carelessly. Coating damage can alter the optical performance of the lenses. While a pair of lenses may seem like a small matter, eye health is what truly matters!