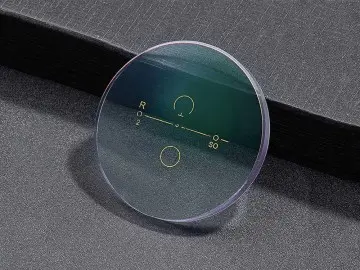

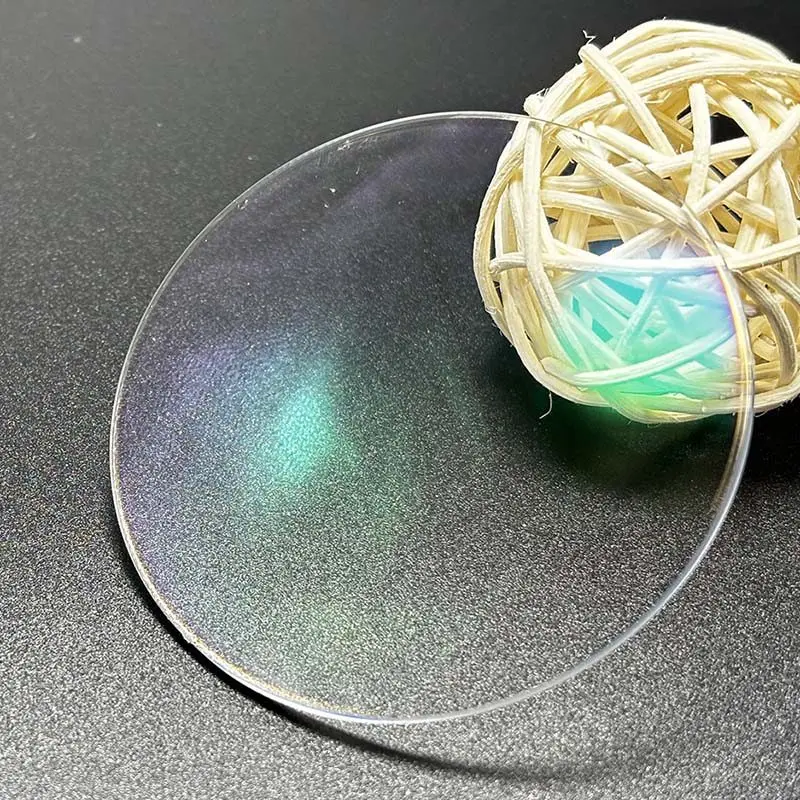

Light Intelligent Photochromic Lenses

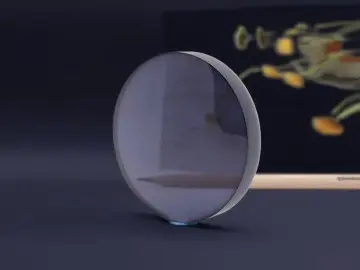

Key Details

Material |

Resin |

Index |

1.56/1.60/1.59/1.67/1.74 |

UV Protection |

UV400 and UV420 |

Abbe Value |

38/42/31/32/33 |

Diameter |

75/70/65mm |

Coating Choice |

HC/HMC/SHMC |

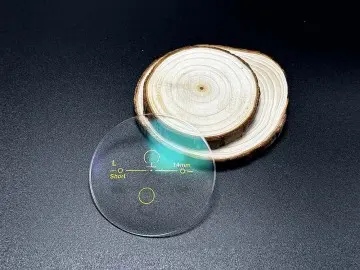

Color Options |

Grey, brown, pink, purple, blue, yellow, orange and green to suit different preferences. |

Other Function Available |

Available in progressive, round-top, flat-top, and blended lens designs for a wide range of uses. |

Product Features

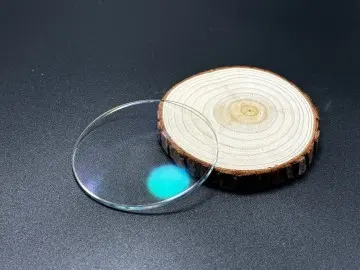

1. The Chemistry of How Photochromic Lenses Work

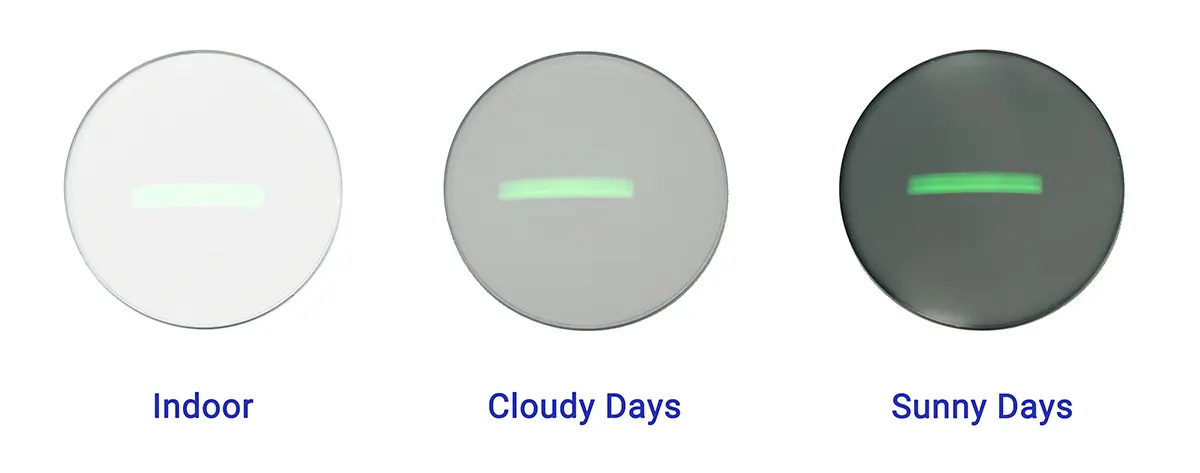

Silver halide (or silver chloride) crystals are evenly scattered in your photochromic lenses. When you wear the photochromic lenses under sunlight, the UV light hits these chemical compounds and triggers a chemical process. The colorless silver halide breaks down into opaque silver atoms and transparent halogen atoms. Then the lenses become dark as more and more silver atoms appear and absorb visible light.

Since the halogens in the photochromic lenses do not disappear, a reversible reaction can occur. When the sunlight diminishes, the silver and halogen undergo recombination and the lenses return to their original bright state.

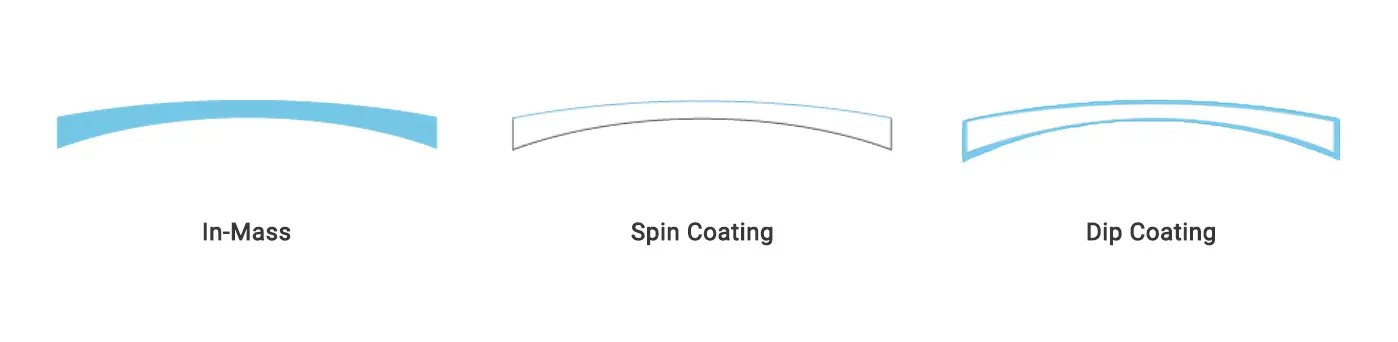

2. Types of Photochromic Technology

Generally speaking, there are two types of photochromic production technology:

In-Mass Photochromic

In-mass photochromic technology has a long and stable history which has been widely used in lens production. It involves dispersing photochromic dye molecules throughout the lens monomer. This means the entire lens can darken and lighten in response to light exposure. It makes the color changing performance stable and lasting. Currently, it is mainly applied to the lenses with 1.56 index.

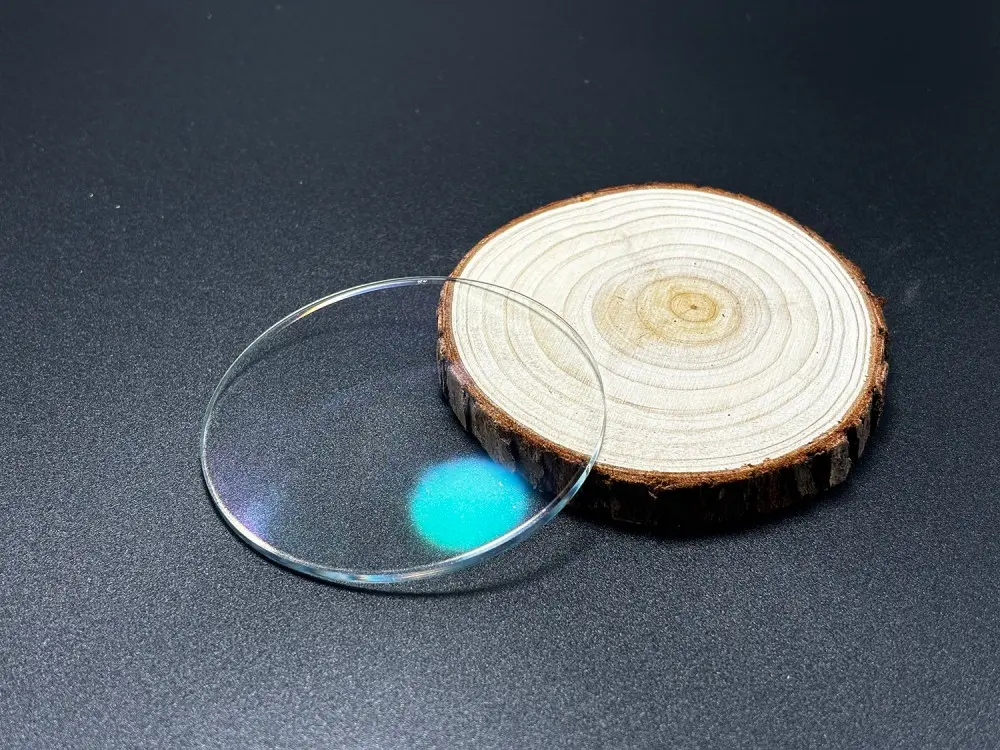

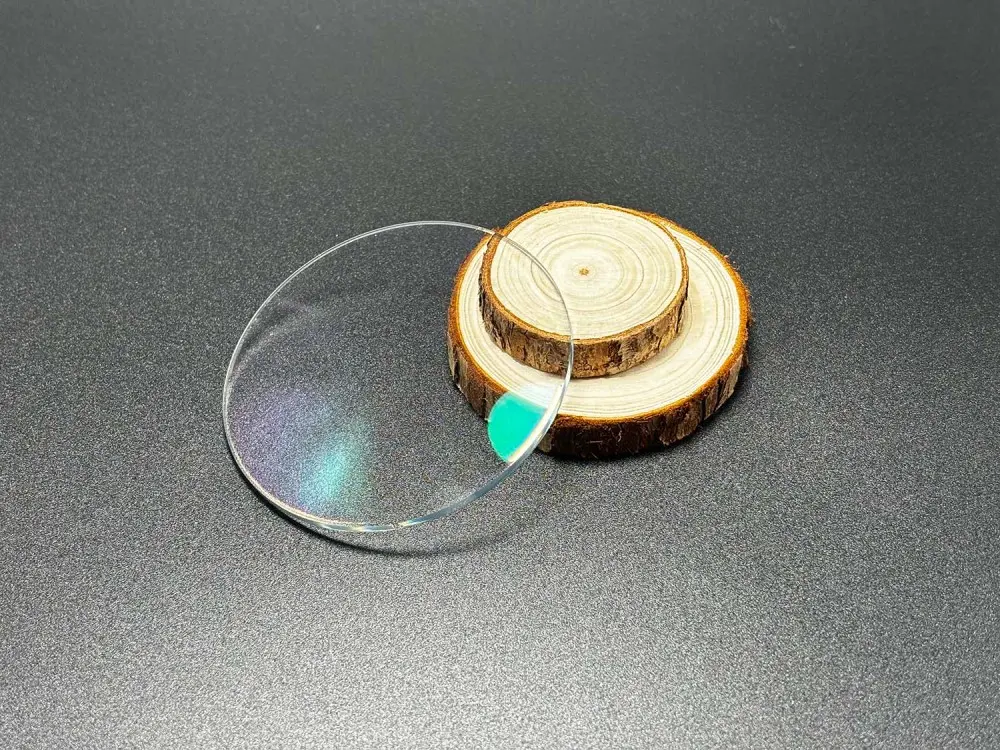

Spin Coating & Dip Coating Photochromic

Spin coating and dip coating are both photochromic coating technology. Spin coating is considered to be a pioneering technology in the manufacture of photochromic lenses. This innovative technique uses the centrifugal force to deposit a photochromic coating film on the surface of the lens, so the color change happens only on the lens surface. The color change speed may be slightly faster than in mass photochromic lenses. It can be applied to different index lenses, such as 1.50, 1.60, 1.67, etc.

Dip coating immerses the lens in a photochromic material solution to coat both sides of the lens with a photochromic layer. It provides a deeper color and better UV protection.