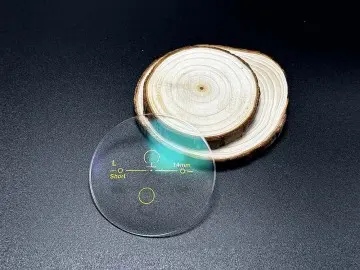

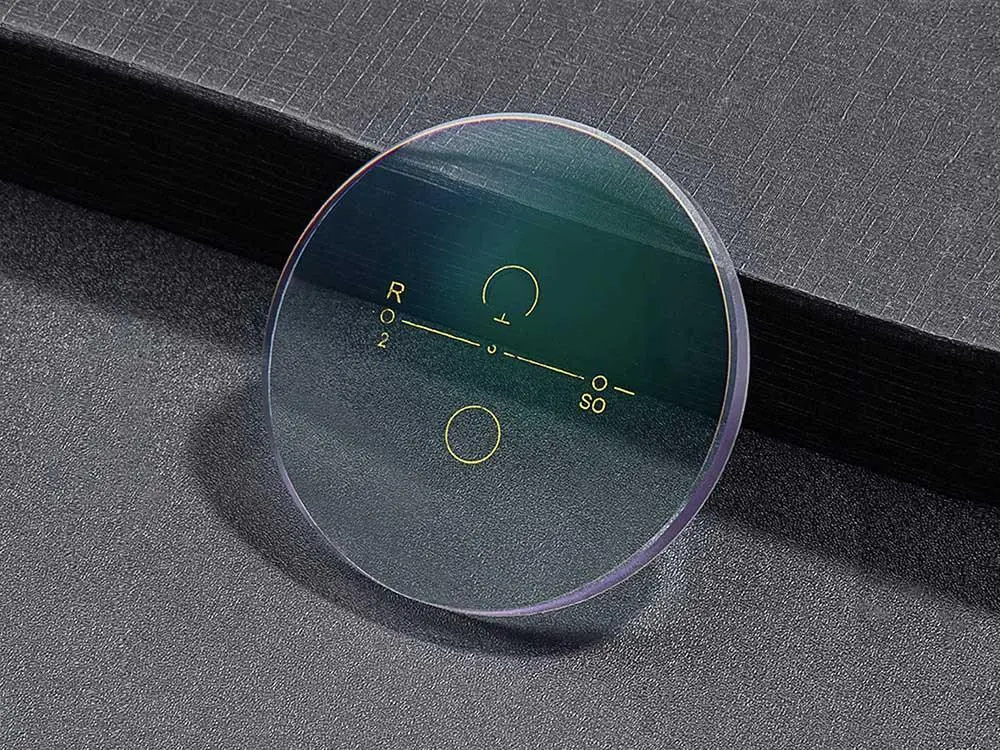

1.56 Semi-Finished Photochromic Progressive Lenses

Product Specification

Material |

Resin |

Index |

1.56 |

Vision Effect |

Progressive & photochromic |

Base Curve |

2,4,6,8 |

Abbe Value |

38 |

Specific Gravity |

1.28 |

Diameter |

75mm 70mm |

Transmission |

99% |

Coating Choice |

HC/HMC/SHMC |

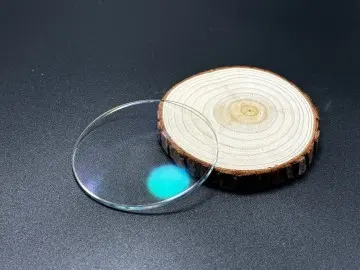

Coating Color |

Green coating & blue coating |

Product Description

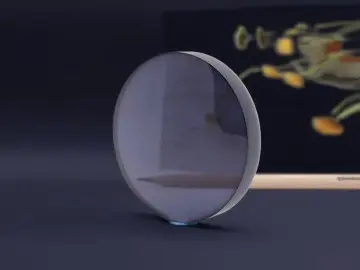

In the manufacture of optical lenses, there are several stages involved in the production of high-quality vision correction lenses. Among them, semi-finished lenses are important intermediate products before making the final customized lenses.

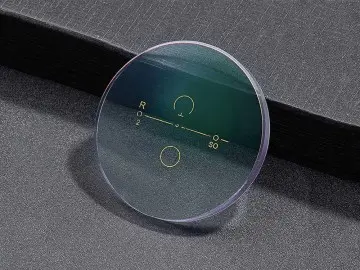

Unlike flat-top bifocal lenses, these progressive lenses have no visible lines in the intermediate zone, eliminating any blurry areas. On the other hand, modern progressive lenses have a smooth and consistent gradation between lens powers. In this sense, they can also be called “multifocal” or “varifocal” lenses because they have all the advantages of the old bifocal or trifocal lenses without the inconvenience and cosmetic drawbacks.

Each lens can be custom-designed according to the wearer's eye position, taking into account the angle between each eye and the lens surface from various viewing directions, to deliver the clearest, sharpest image possible and enhance peripheral vision.

More Information

Many factories stock a wide range of semi-finished lenses. But how are they made? Here are several key stages:

Step 1. Material Selection: Lens materials include Cr39 resin, Polycarbonate, high-index resin and mineral glass. Raw liquid monomers are selected based on the desired refractive index, impact resistance and other properties.

Step 2. Various Additives Mixing: Some additives like photochromic dyes or tints will be mixed with the monomers if needed.

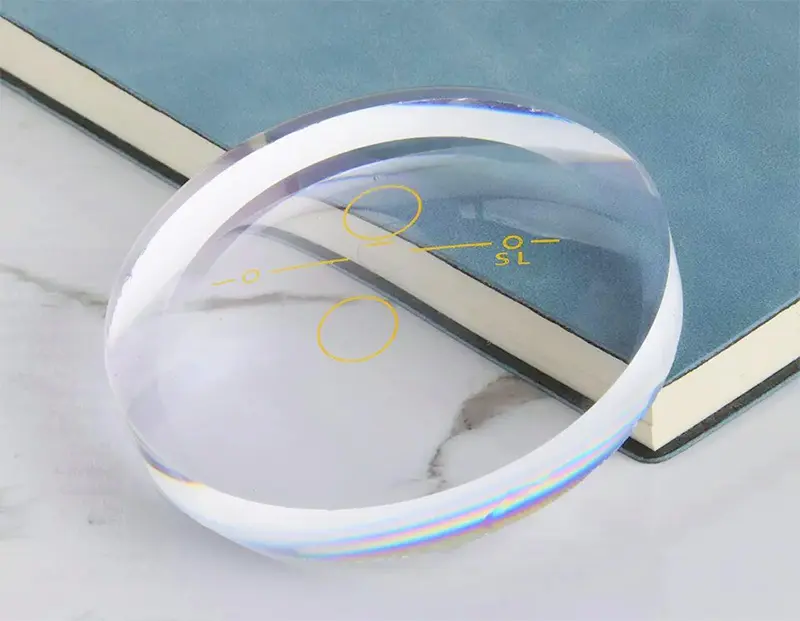

Step 3. Forming the Blank: The selected raw material is cast or injected into specially designed molds. The front surface of the mold determines the base curve and optical properties. Once solidified or cooled, the material forms a lens blank.

Step 4. Front Surface Processing: After the initial blank is molded, the next critical step is to machine the front surface to an exact optical finish. The front surface of the lens blank is ground and polished to create a specific curvature. This standardized base curve is designed to accommodate a wide range of prescriptions. The back surface remains unprocessed to allow for precise customization during subsequent steps.

Step 5. Quality Inspection: After the front surface is finished, the semi-finished blanks undergo rigorous quality checks for surface smoothness, optical accuracy, and surface defects like bubbles, ripples or scratches.

Step 6. Optional Pre-Coatings: Some semi-finished lenses may receive initial coatings like hard coating and UV coating at this stage.